ExperimentGasChromatography

ExperimentGasChromatography[Samples]⟹Protocol

generates a Protocol to analyze Samples using gas chromatography (GC).

Gas chromatography (often abbreviated GC) is a chromatographic separation process wherein a mixture of volatilizable analytes is vaporized and passed through a capillary column where the gas-phase mixture is separated via interaction with the solid/liquid stationary phase coating the capillary walls. Preferential adsorption of some analytes over others takes place on the column's stationary phase as the gas-phase analytes move through the column, causing analytes to elute from the column at different times depending on the nature of the interaction between each analyte and the stationary phase. At the end of the column, the separated analytes can be measured one by one using a variety of destructive (flame or barrier discharge ionization), mass sensitive (mass spectrometry), and/or physicochemical (thermal conductivity) detection techniques.

Experimental Principles

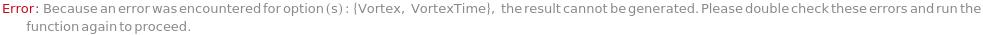

Figure 1.1: Procedural overview of a gas chromatography experiment. Step 1: A fresh inlet septum, liner, and O-ring are installed and the column is attached to the inlet. Step 2: The column is conditioned if it has been installed after being stored outside the instrument. Step 3: The column is attached to the specified detector. Step 4: Samples, standards, and blanks are injected onto the separatory column. Step 5: The analytes contained in each injection are separated according to boiling point and interaction with the column stationary phase. Step 6: Upon exit from the column, the now-separated analytes are detected by the specified detector.

Instrumentation

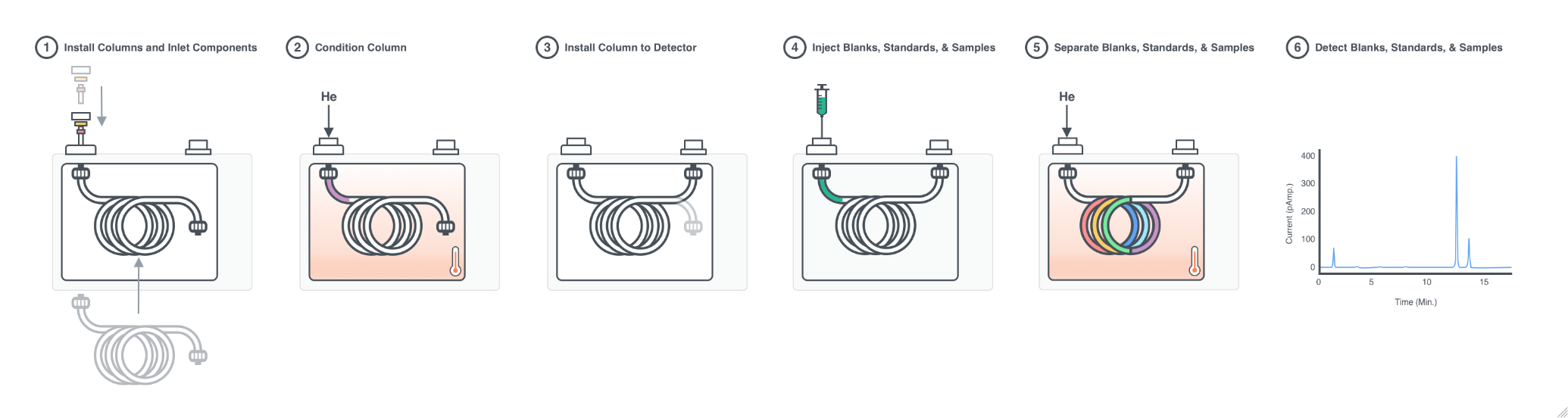

Agilent 8890 GCMS

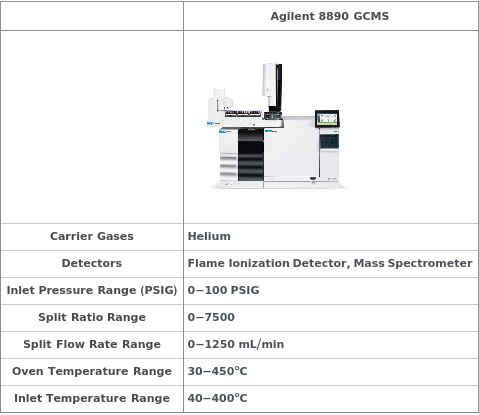

Figure 2.1.1: Samples to be separated by gas chromatography are placed in sample vials on the autosampler, in the sample holder module (3) pictured above, which can hold up to 45 HeadspaceVial footprint containers or 162 samples in CEVial footprint containers. Recommended containers can be found in the preferred containers section below.

Samples may be diluted using up to 3 unique DilutionSolvents from the (2) solvent storage module, spun rapidly to mix using the (6) vortex mixing module, or shaken and incubated using the (7) agitation mixing module. When the samples are ready for injection, a syringe tool from the (1) syringe tool storage module may be used to draw or adsorb from a liquid sample or the headspace above any sample. The syringe tool storage module can hold one syringe for each available SamplingMethod. If samples are to be prepared by a Solid-Phase MicroExtraction (SPME), the SPME fiber may be conditioned by heating in flowing Helium. For more information on sample preparation, see Figures 3.2-3.11 below.

Samples prepared in a syringe tool are injected into the temperature-controlled Inlet, where the analytes in the sample are vaporized into a continuous flow of carrier gas moving through the Inlet onto the Column. The column is connected to the specified Inlet (see Figure 3.1) at its inlet, and to a specified Detector (see Figures 3.12 and 3.13) at its outlet. As the analytes pass through the column, the temperature and flow rate of carrier gas passing through the column can be adjusted to optimize separation performance and peak detection.

Experiment Options

General

Instrument

The gas chromatograph used to separate analytes in a sample in the gas phase within a capillary stationary phase during this experiment.

Pattern Description: An object of type or subtype Model[Instrument, GasChromatograph] or Object[Instrument, GasChromatograph]

Programmatic Pattern: ObjectP[{Model[Instrument, GasChromatograph], Object[Instrument, GasChromatograph]}]

Inlet

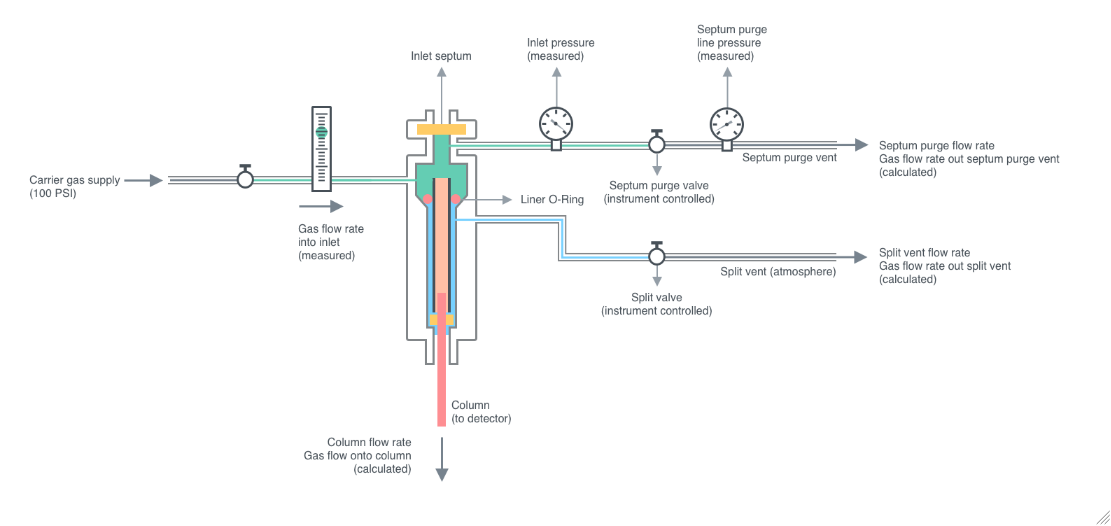

The heated antechamber attached to the column into which the samples to be analyzed will be injected, and where those samples will be subsequently vaporized and pushed onto the column. See Figure 3.1 for more information about the inlet.

Figure 3.1: Carrier supply zone (green): This volume of the inlet contains clean carrier gas. The septum purge flow rate is calculated based on the difference in pressure between the inlet and the septum purge line. This flow ensures a constant refreshing of the carrier supply zone volume upstream of the vaporization chamber so that back-diffusion of vaporized analytes does not contaminate the carrier gas supply.

Vaporization chamber zone (orange) : This is the volume of the inlet within the inlet liner where the sample is introduced. The injection syringe penetrates the inlet septum, and the syringe's needle tip stops inside this volume, at which point the contents of the syringe are dispensed (or exposed, in the case of the SPME fiber) and vaporized. Vaporized analytes in this part of the inlet will flow onto the column and into the split vent zone.

Split vent zone (blue): This is the volume of gas the inlet outside (surrounding) the inlet liner. When the split valve is open, some of the flow from the carrier supply passes through vaporization chamber zone and bypasses the entrance to the separatory column into this zone, after which it exits the inlet through the split valve. The act of "splitting" the flow through the inlet onto both the column and out the split valve has two main functions: First, it can be used to effectively dilute the injected sample after vaporization. Second, it can be used to purge the inlet volume with clean carrier gas so that residual vapors are removed from the inlet and do not slowly enter the column for an extended period of time after sample injection.

During operation of the inlet, gas flows from the green carrier supply zone into the orange vaporization chamber zone, and from the orange vaporization chamber zone into both the column and the blue split vent zone.

InletLiner

The glass insert placed inside the inlet into which the sample is injected (to minimize any reaction of the analytes with the metal walls of the inlet) that will be installed in the inlet during this experiment. See Figure 3.1 for more information about the inlet.

Pattern Description: An object of type or subtype Model[Item, GCInletLiner] or Object[Item, GCInletLiner]

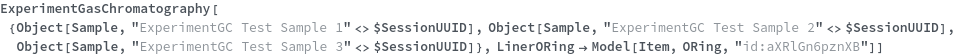

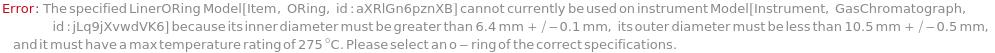

LinerORing

A compressible ring that forms a seal separating the inlet volume from the septum purge volume in the inlet, to be installed in the inlet during this experiment. See Figure 3.1 for more information about the inlet.

Default Calculation: Selects a fluoroelastomer O-ring unless the inlet temperature is above 350 C, in which case graphite will be selected.

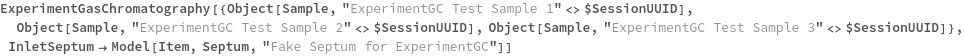

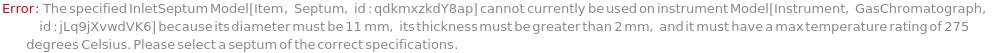

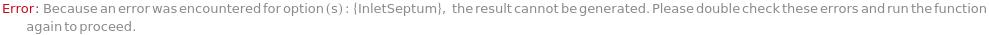

InletSeptum

The barrier that the injection syringe will penetrate to inject the sample into the inlet, to be installed in the inlet during this experiment. See Figure 3.1 for more information about the inlet.

Default Calculation: Selects an Advanced Green septum unless the inlet temperature is above 350 C, in which case a bleed & temperature optimized septum will be selected.

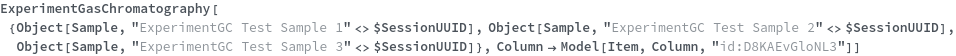

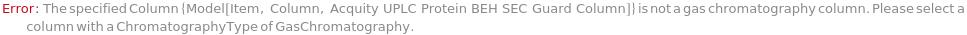

Column

The capillary tube containing a wall-coated stationary phase into which injected samples are carried from the inlet by the continuous flow of carrier gas. As the sample flows through the column, analytes in each injected sample are separated according to their differing interaction with the column stationary phase and boiling points.

Default Value: {Model[Item, Column, HP-5ms Ultra Inert, 30 m, 0.25 mm ID, 0.25 μm film thickness, 7 inch cage]}

Pattern Description: An object of type or subtype Model[Item, Column] or Object[Item, Column] or {Model[Item, Column, HP-5ms Ultra Inert, 30 m, 0.25 mm ID, 0.25 μm film thickness, 7 inch cage]}

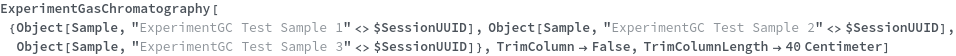

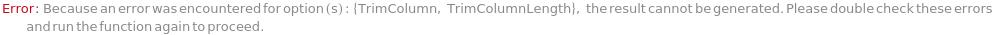

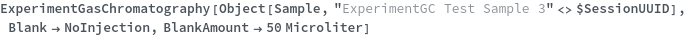

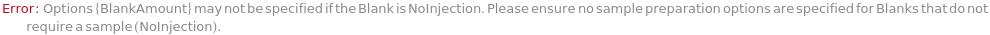

TrimColumn

Indicates whether or not a length of the inlet end of the column will be separated from the remainder of the column and discarded, typically in an attempt to remove contamination of the inlet end of the column that may result from injections of samples containing nonvolatile and/or reactive compounds.

TrimColumnLength

The length of the inlet end of the column to separate from the column and discard prior to installation of the column into the gas chromatograph.

Pattern Description: Greater than or equal to 0 meters and less than or equal to 100 meters or Null.

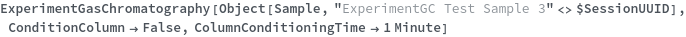

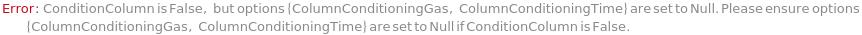

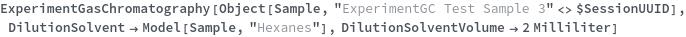

ConditionColumn

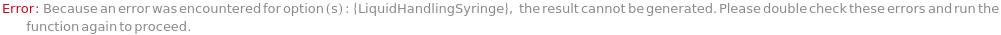

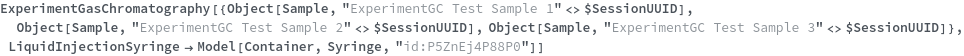

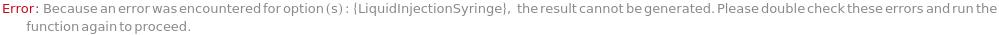

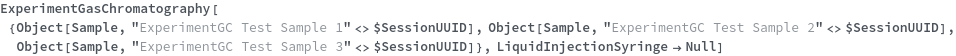

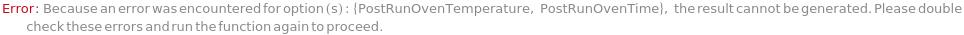

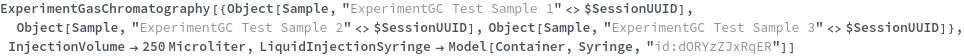

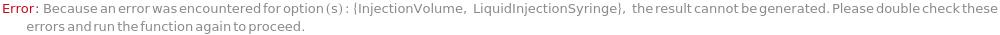

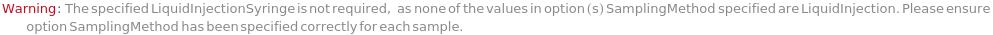

LiquidInjectionSyringe

The combination of plunger, cylinder, and needle that will be used to penetrate the sample vial cap to aspirate a liquid sample that will be injected onto the column.

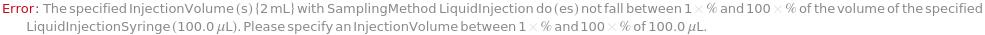

Default Calculation: If a liquid injection sample is specified, selects the smallest available liquid injection syringe that can accommodate the largest specified injection volume.

Pattern Description: An object of type or subtype Model[Container, Syringe] or Object[Container, Syringe] or Null.

Programmatic Pattern: (ObjectP[{Model[Container, Syringe], Object[Container, Syringe]}] | Automatic) | Null

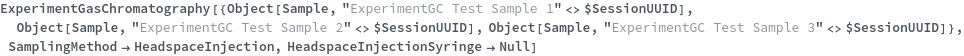

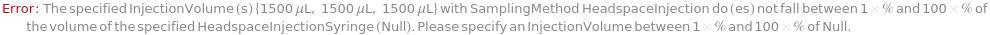

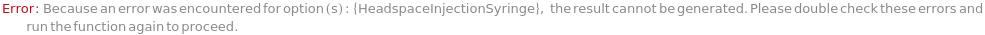

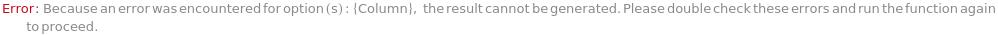

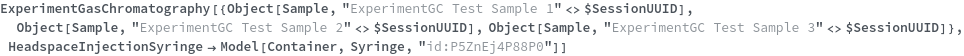

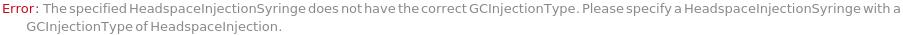

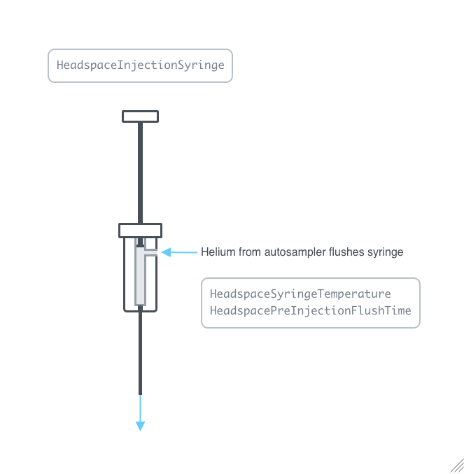

HeadspaceInjectionSyringe

The combination of plunger, cylinder, and needle that will be used to penetrate the sample vial cap to aspirate a sample of the vial's gas volume (headspace) that will be injected onto the column.

Default Calculation: If a headspace injection sample is included, automatically selects a 2.5 mL headspace injection syringe.

Pattern Description: An object of type or subtype Model[Container, Syringe] or Object[Container, Syringe] or Null.

Programmatic Pattern: (ObjectP[{Model[Container, Syringe], Object[Container, Syringe]}] | Automatic) | Null

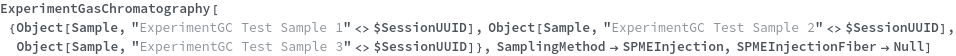

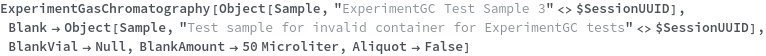

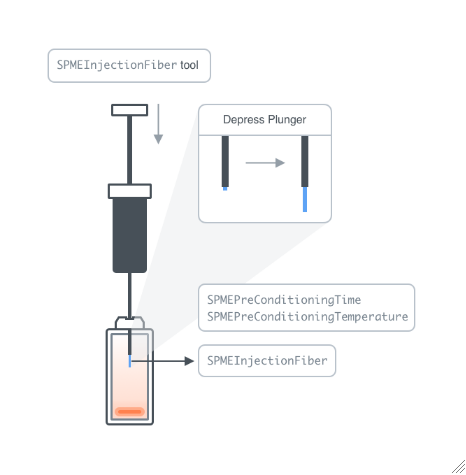

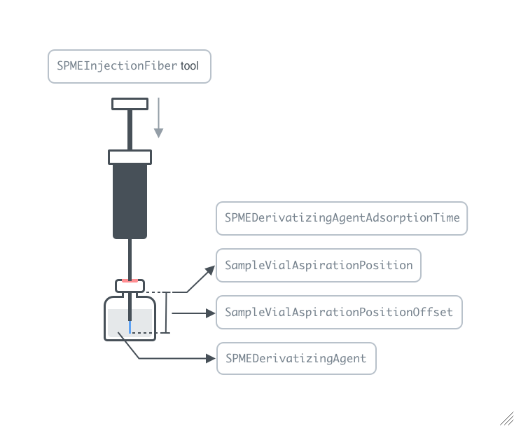

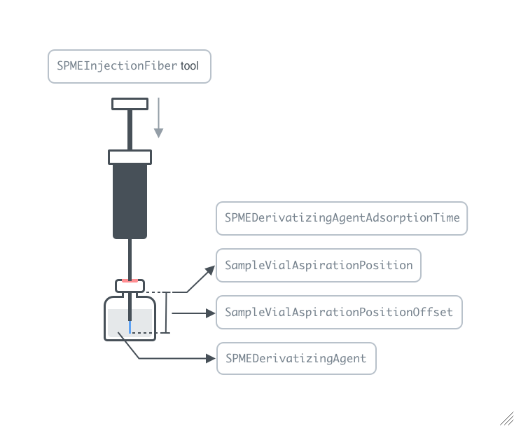

SPMEInjectionFiber

The filament of a stationary phase matrix with retractable sheath that will be used to selectively adsorb analytes from a sample matrix during a Solid Phase MicroExtraction (SPME), and then desorb those analytes onto the column.

Default Calculation: If Solid Phase MicroExtraction (SPME) injections are specified, a 30 μm film thickness polydimethylsiloxane (PDMS) fiber will be used.

Pattern Description: An object of type or subtype Model[Item, SPMEFiber] or Object[Item, SPMEFiber] or Null.

Programmatic Pattern: (ObjectP[{Model[Item, SPMEFiber], Object[Item, SPMEFiber]}] | Automatic) | Null

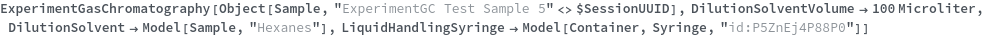

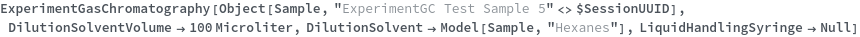

LiquidHandlingSyringe

The combination of plunger, cylinder, and needle that will be used to transfer liquid from specified dilution solvents into samples on the GC autosampler deck.

Default Calculation: Automatically selects a 2.5 mL liquid handling syringe if sample dilutions are specified.

Pattern Description: An object of type or subtype Model[Container, Syringe] or Object[Container, Syringe] or Null.

Programmatic Pattern: (ObjectP[{Model[Container, Syringe], Object[Container, Syringe]}] | Automatic) | Null

Gas Input Configuration

CarrierGas

The gas to be used to push the vaporized analytes through the column during chromatographic separation of the samples injected into the gas chromatograph.

Column Preparation

ColumnConditioningGas

The carrier gas used to purge the column(s) during the column conditioning step, which occurs when the column is installed.

ColumnConditioningTime

The time for which carrier gas will be flowed through the column while it is heated to remove oxygen, water vapor, and other impurities that may have accumulated in the column during disuse prior to separation of standards and samples in the column during the experiment.

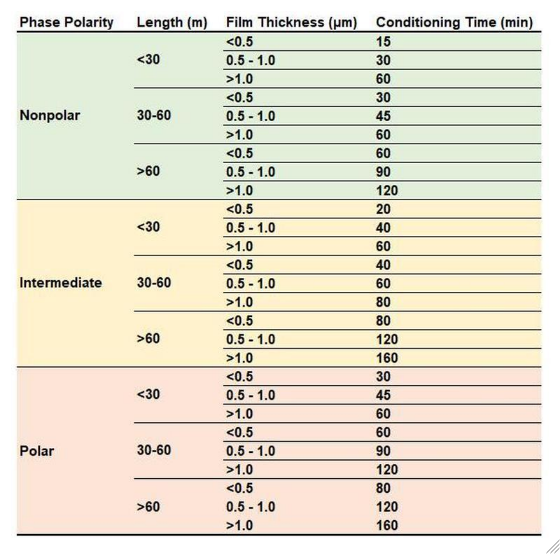

Figure 3.2: Suggested conditioning times for GC columns as a function of the stationary phase polarity, length, and film thickness.

Default Calculation: The column conditioning time will be determined by the column length and polarity of the stationary phase according to Figure 3.2

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 999.99 minutes or Null.

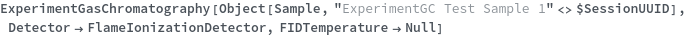

ColumnConditioningTemperature

The temperature at which the column will be incubated while carrier gas is flowed through the column while it is heated to remove oxygen, water vapor, and other impurities that may have accumulated in the column during disuse prior to separation of standards and samples in the column during the experiment.

Default Calculation: The column conditioning temperature will be set to 20 Celsius above the highest temperature setpoint to be used during separation of the analytes, or the MaxColumnTemperature, whichever is lower.

Pattern Description: Ambient or greater than or equal to 30 degrees Celsius and less than or equal to 450 degrees Celsius or Null.

Solvent Configuration

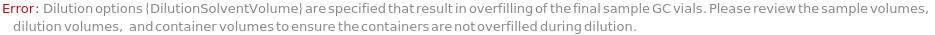

DilutionSolvent

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

SecondaryDilutionSolvent

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

TertiaryDilutionSolvent

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

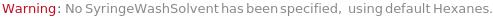

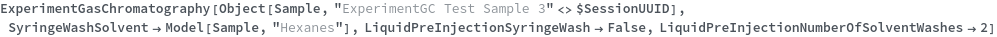

SyringeWashSolvent

A liquid solution that will be used to flush the LiquidInjectionSyringe to remove residual impurities in the syringe prior to aspiration of the sample.

Default Calculation: Automatically set to hexanes if any pre-injection liquid syringe washing options using this solvent are specified.

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

SecondarySyringeWashSolvent

A liquid solution that will be used to flush the LiquidInjectionSyringe to remove residual impurities in the syringe prior to aspiration of the sample.

Default Calculation: Automatically set to hexanes if any pre-injection liquid syringe washing options using this solvent are specified.

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

TertiarySyringeWashSolvent

A liquid solution that will be used to flush the LiquidInjectionSyringe to remove residual impurities in the syringe prior to aspiration of the sample.

Default Calculation: Automatically set to hexanes if any pre-injection liquid syringe washing options using this solvent are specified.

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

QuaternarySyringeWashSolvent

A liquid solution that will be used to flush the LiquidInjectionSyringe to remove residual impurities in the syringe prior to aspiration of the sample.

Default Calculation: Automatically set to hexanes if any pre-injection liquid syringe washing options using this solvent are specified.

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

Sample Preparation

Dilute

Indicates whether or not an aliquot of a specified liquid solution will be added to the sample's container prior to injection of the sample.

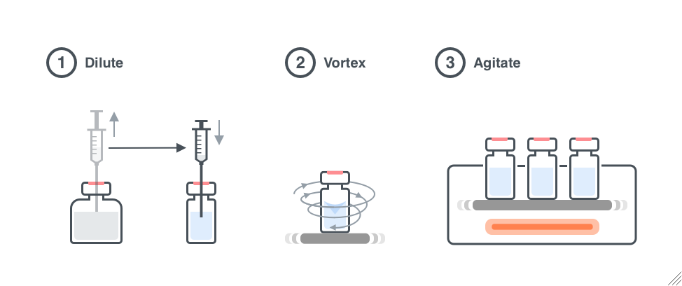

Figure 3.3: Samples on the autosampler are prepared in the indicated order prior to injection via the specified SamplingMethod: First, samples may be diluted using the DilutionSolvents in the solvent storage module (see Figure 2.1). Second, samples may be vortexed in the vortex mixing module. Third, samples may be shaken and incubated using the agitation mixing module.

DilutionSolventVolume

The volume of the DilutionSolvent to aliquot into the sample's container prior to injection of the sample.

Default Calculation: Automatically fills the sample's container to the sample container's MaxVolume with an equal volume mixture of each DilutionSolvent specified and the sample if Dilute is True.

Pattern Description: Greater than or equal to 25 microliters and less than or equal to 2500 microliters or Null.

SecondaryDilutionSolventVolume

The volume of the DilutionSolvent to aliquot into the sample's container prior to injection of the sample.

Default Calculation: Automatically fills the sample's container to the sample container's MaxVolume with an equal volume mixture of each DilutionSolvent specified and the sample if Dilute is True.

Pattern Description: Greater than or equal to 25 microliters and less than or equal to 2500 microliters or Null.

TertiaryDilutionSolventVolume

The volume of the DilutionSolvent to aliquot into the sample's container prior to injection of the sample.

Default Calculation: Automatically fills the sample's container to the sample container's MaxVolume with an equal volume mixture of each DilutionSolvent specified and the sample if Dilute is True.

Pattern Description: Greater than or equal to 25 microliters and less than or equal to 2500 microliters or Null.

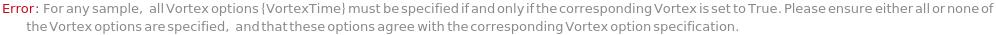

Vortex

VortexMixRate

The rate (in RPM) at which the sample will be spun in place to mix (vortexed) in the vortex mixer prior to analysis.

Pattern Description: Greater than or equal to 0 revolutions per minute and less than or equal to 2000 revolutions per minute or Null.

VortexTime

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 100 seconds or Null.

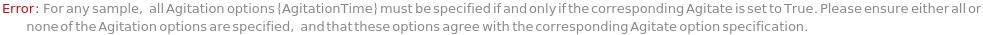

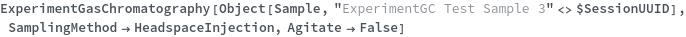

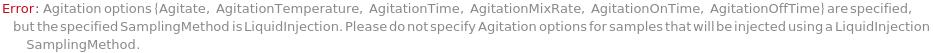

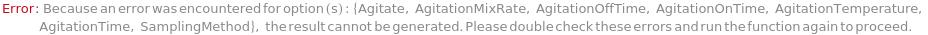

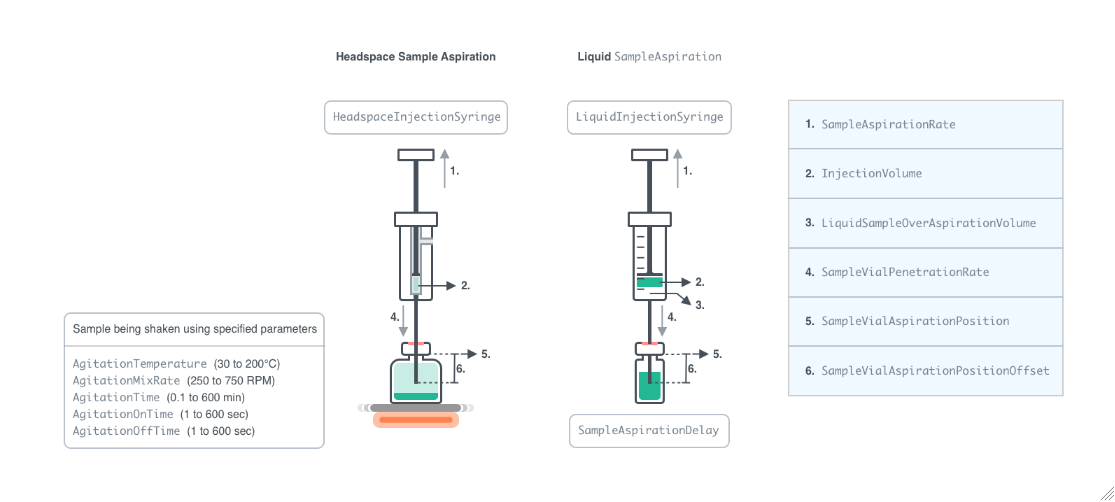

Agitate

Indicates whether or not the sample will be mixed by swirling the sample's container for a specified time at a specified rotational speed and incubated at a specified temperature prior to sampling.

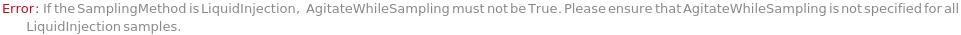

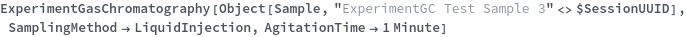

AgitationTime

The time that each sample will be mixed by swirling the sample's container for a specified time at a specified rotational speed and incubated at a specified temperature in the agitator prior to sample aspiration for injection onto the column.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

AgitationTemperature

The temperature at which each sample will be mixed by swirling the sample's container for a specified time at a specified rotational speed and incubated at a specified temperature in the agitator prior to sample aspiration for injection onto the column.

Pattern Description: Ambient or greater than or equal to 30 degrees Celsius and less than or equal to 200 degrees Celsius or Null.

AgitationMixRate

Pattern Description: Greater than or equal to 250 revolutions per minute and less than or equal to 750 revolutions per minute or Null.

AgitationOnTime

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 600 seconds or Null.

AgitationOffTime

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 600 seconds or Null.

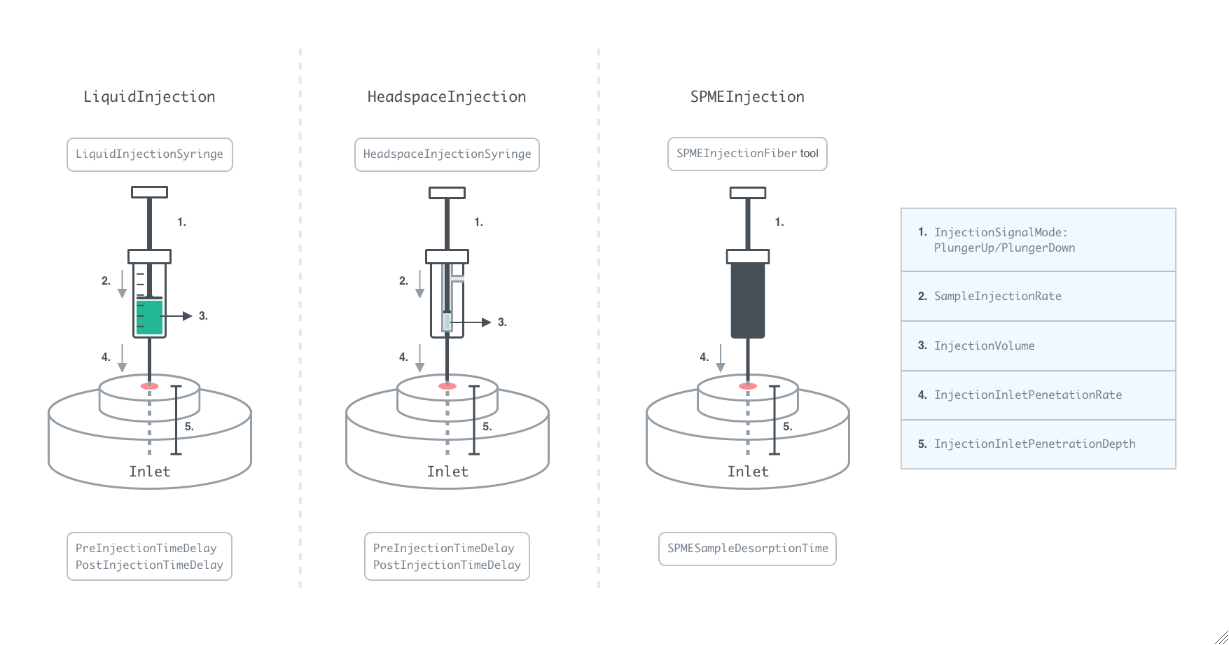

Sampling Method

SamplingMethod

The process by which a sample will be aspirated or analytes extracted in preparation for injection of those analytes onto the column to be separated.

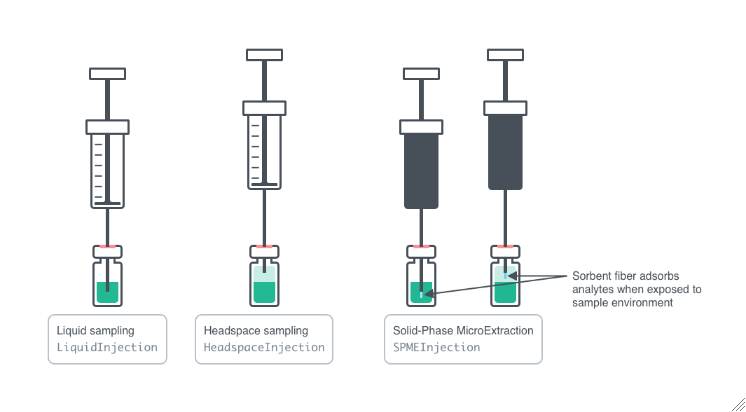

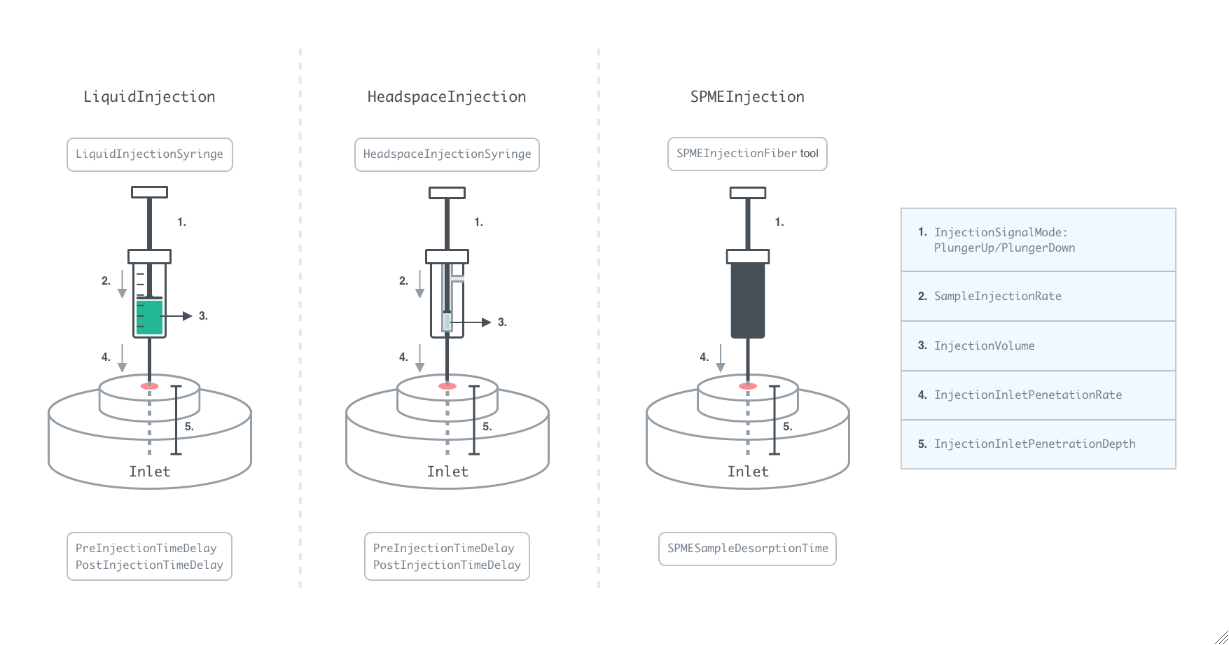

Figure 3.4: Three sampling methods are available for sample injection onto the column. In LiquidInjection, shown on the left, microliters of a liquid sample are aspirated, then injected into the inlet where the liquid is vaporized and pushed onto the column by the continuously flowing carrier gas. In HeadspaceInjection, shown in center, milliliters of the vapor present above the sample in a sealed container are aspirated into a gas-tight syringe. This gas can be injected directly onto the column through the inlet, without the need to vaporize the sample rapidly using a high inlet temperature. In SPMEInjection, shown at right, a Solid-Phase MicroExtraction may be carried out on either a liquid sample or the headspace above a sample using a sorbent fiber. The composition of the fiber, adsorption time, and temperature of the extraction will determine which analytes are sorbed onto the fiber. The fiber is then inserted into the heated inlet to desorb the analytes, where they are pushed onto the column by the continuous carrier gas flow rate through the inlet.

Default Calculation: Selects a SamplingMethod of LiquidInjection unless the sample does not contain a liquid component, in which case HeadspaceInjection is selected.

Pre-Injection Syringe Preparation

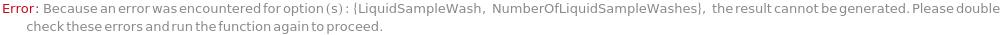

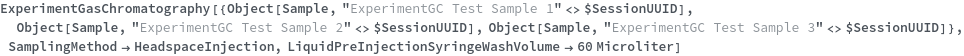

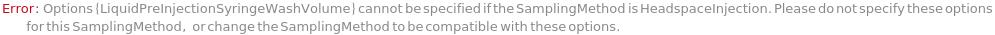

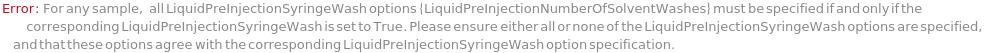

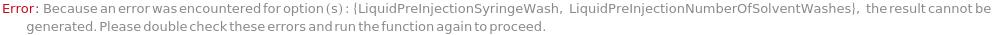

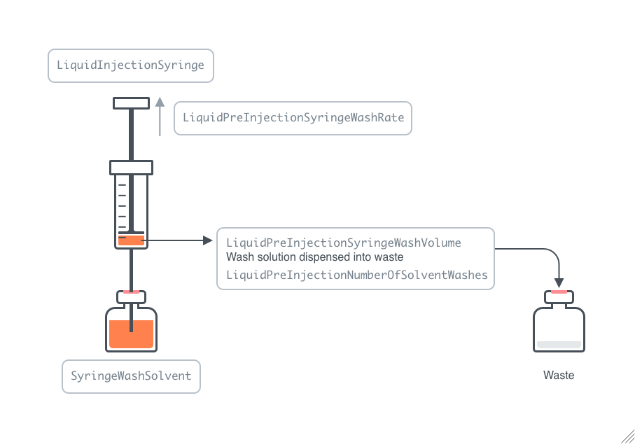

LiquidPreInjectionSyringeWash

Indicates whether the liquid injection syringe will be (repeatedly) filled with a volume of solvent which will subsequently be discarded, in an attempt to remove any impurities present prior to sample aspiration.

Figure 3.5: Prior to aspiration of a LiquidInjection sample, the LiquidInjectionSyringe may be washed using up to four syringe wash solvents stored on the autosampler's syringe wash module (Figure 2.1). The washing is performed by repeatedly aspirating a volume of wash solvent into the syringe, and then dispensing that volume into a waste container in the syringe wash module.The options shown in this figure provide control over this process.

Default Calculation: Automatically set to True if any pre-injection liquid syringe washing options are specified.

LiquidPreInjectionSyringeWashVolume

The volume of the syringe wash solvent to aspirate and dispense using the liquid injection syringe in an attempt to remove any impurities present prior to sample aspiration.

Default Calculation: Automatically set to the InjectionVolume if any pre-injection liquid syringe washing options are specified.

Pattern Description: Greater than or equal to 1 microliter and less than or equal to 100 microliters or Null.

LiquidPreInjectionSyringeWashRate

The aspiration rate that will be used to draw and dispense syringe wash solvent(s) in an attempt to remove any impurities present prior to sample aspiration.

Default Calculation: Automatically set to the 5 microliters per second if any pre-injection liquid syringe washing options are specified.

Pattern Description: Greater than or equal to 0.1 microliters per second and less than or equal to 100 microliters per second or Null.

LiquidPreInjectionNumberOfSolventWashes

The number of times to aspirate and discard a volume the specified SyringeWashSolvent prior to aspirating the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any pre-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

LiquidPreInjectionNumberOfSecondarySolventWashes

The number of times to aspirate and discard a volume the specified SecondarySyringeWashSolvent prior to aspirating the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any pre-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

LiquidPreInjectionNumberOfTertiarySolventWashes

The number of times to aspirate and discard a volume the specified TertiarySyringeWashSolvent prior to aspirating the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any pre-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

LiquidPreInjectionNumberOfQuaternarySolventWashes

The number of times to aspirate and discard a volume the specified QuaternarySyringeWashSolvent prior to aspirating the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any pre-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

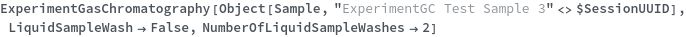

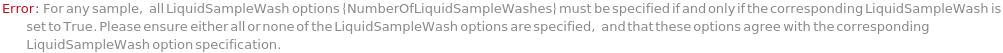

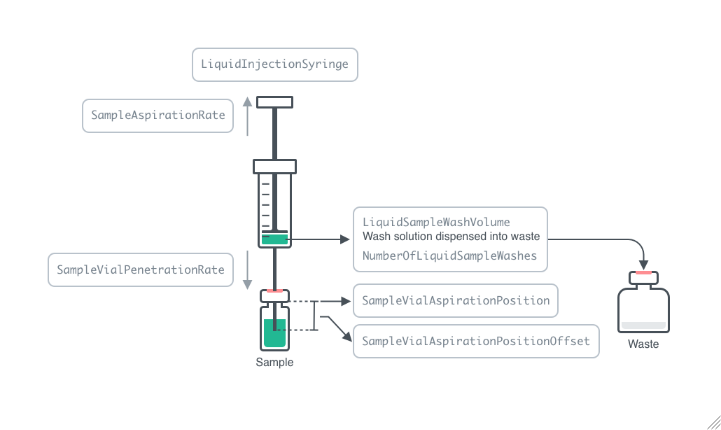

LiquidSampleWash

Default Calculation: Automatically set to True for all samples with a corresponding SamplingMethod of LiquidInjection.

NumberOfLiquidSampleWashes

The number of times to aspirate and discard a volume of the sample using the liquid injection syringe in an attempt to remove any impurities present prior to sample aspiration.

Figure 3.6: Prior to aspiration of a LiquidInjection sample, the LiquidInjectionSyringe may also be washed using the sample itself to minimize contamination from previous injections or washing using a syringe wash solvent. A specified number of volumes of sample are aspirated and then dispensed into a waste container in the syringe wash module.The options shown in this figure provide control over this process.

LiquidSampleWashVolume

The volume of the sample that will be aspirateed and discarded in an attempt to remove any impurities in the liquid injection syringe prior to sample aspiration.

Default Calculation: Automatically set to 125% of the InjectionVolume or the maximum volume of the injection syringe, whichever is smaller, if LiquidSampleWash is True.

Pattern Description: Greater than or equal to 0.01 microliters and less than or equal to 100 microliters or Null.

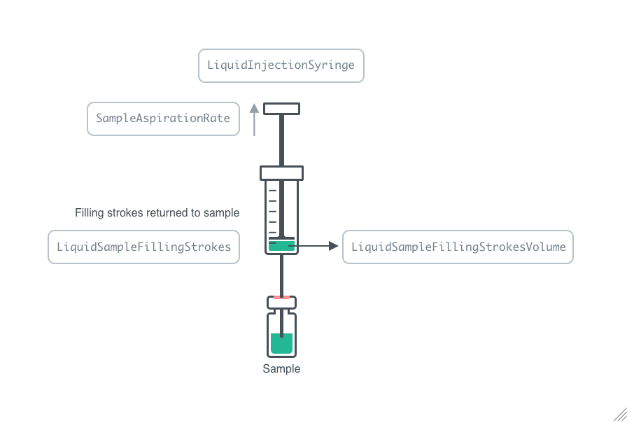

LiquidSampleFillingStrokes

The number of times to aspirate and rapidly dispense the sample in an attempt to eliminate any bubbles from the cylinder of the liquid injection syringe prior to sample aspiration.

Figure 3.7: When a LiquidInjection sample is aspirated, the specified sample volume may be repeatedly aspirated and dispensed back into the sample container to eliminate bubbles from the aspirated mixture.The options shown in this figure provide control over this process.

LiquidSampleFillingStrokesVolume

The volume the sample to be aspirated and rapidly dispensed in an attempt to eliminate any bubbles from the cylinder of the liquid injection syringe prior to sample aspiration.

Default Calculation: Automatically set to 125% of the InjectionVolume or the total syringe volume, whichever is smaller, if a number of LiquidSampleFillingStrokes is set.

Pattern Description: Greater than or equal to 0 microliters and less than or equal to 100 microliters or Null.

LiquidFillingStrokeDelay

The amount of time to wait for any remaining bubbles to settle after aspirating and rapidly dispensing the sample in an attempt to eliminate any bubbles from the cylinder of the liquid injection syringe prior to sample aspiration.

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 10 seconds or Null.

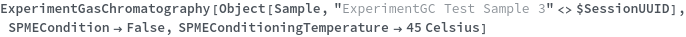

SPMECondition

Indicates whether or not the Solid Phase MicroExtraction (SPME) fiber will be heat-treated in a flow of Helium prior to sample extraction to desorb residual analytes from the fiber.

Figure 3.8: Prior to extraction of a SPMEInjection sample, the SPMEInjectionFiber may be conditioned (treated at elevated temperature in a flowing stream of Helium) in the SPME fiber conditioning module (Figure 2.1) to desorb any residual contamination from a prior extraction or environment.The options shown in this figure provide control over this process.

SPMEConditioningTemperature

The temperature at which the Solid Phase MicroExtraction (SPME) fiber will be heat-treated in flowing Helium prior to sample extraction to desorb residual analytes from the fiber.

Default Calculation: If SPMECondition is True, automatically set to the minimum recommended conditioning temperature associated with the SPME fiber.

Pattern Description: Greater than or equal to 40 degrees Celsius and less than or equal to 350 degrees Celsius or Null.

SPMEPreConditioningTime

The amount of time for which the Solid Phase MicroExtraction (SPME) fiber will be heat-treated in flowing Helium prior to sample extraction to desorb residual analytes from the fiber.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

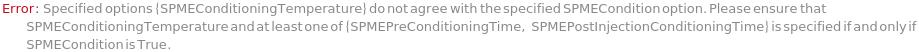

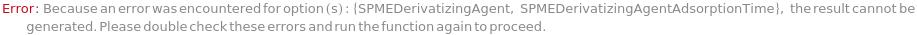

SPMEDerivatizingAgent

The matrix in which the Solid Phase MicroExtraction (SPME) fiber will be allowed to react prior to sample extraction.

Figure 3.9: Prior to extraction of a SPMEInjection sample, the SPMEInjectionFiber may also be treated in a reagent or solvent solution stored in the solvent storage module on the autosampler (Figure 2.1) to give the sorbent fibers the desired chemical properties to adsorb analytes of interest from the sample. The options shown in this figure provide control over this process.

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

SPMEDerivatizingAgentAdsorptionTime

The amount of time for which the Solid Phase MicroExtraction (SPME) fiber will be allowed to react in the specified derivatizing agent prior to sample extraction.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

SPMEDerivatizationPosition

The extremity of the sample vial (Top or Bottom) where the tip of the Solid Phase MicroExtraction fiber will be positioned during sample aspiration or extraction.

SPMEDerivatizationPositionOffset

The distance from the specified extremity of the sample vial (Top or Bottom) where the tip of the Solid Phase MicroExtraction fiber will be positioned during sample aspiration or extraction.

Pattern Description: Greater than or equal to 10 millimeters and less than or equal to 70 millimeters or Null.

Sample Aspiration

SampleVialAspirationPosition

The extremity of the sample vial (Top or Bottom) where the tip of the injection syringe's needle or Solid Phase MicroExtraction fiber will be positioned during sample aspiration or extraction.

Figure 3.10: LiquidInjection and HeadspaceInjection samples are aspirated in a similar manner. The syringe needle is plunged into the sample vial at the SampleVialPenetrationRate, where it is positioned using the SampleVialAspirationPosition and SampleVialAspirationPositionOffset. The InjectionVolume of sample is drawn into the syringe at the SampleAspirationRate. LiquidInjection samples may also over aspirate a specified LiquidSampleOverAspirationVolume. HeadspaceInjection samples are continuously mixed during sample aspiration according to the specified agitation parameters above.

SampleVialAspirationPositionOffset

The distance from the specified extremity of the sample vial (Top or Bottom) where the tip of the injection syringe's needle or Solid Phase MicroExtraction fiber will be positioned during sample aspiration or extraction.

Default Calculation: Automatically set to 30 mm if SamplingMethod is LiquidInjection, 15 mm if SamplingMethod is HeadspaceInjection, or 40 mm if SamplingMethod is SPMEInjection.

Pattern Description: Greater than or equal to 0.1 millimeters and less than or equal to 65 millimeters.

SampleVialPenetrationRate

The velocity at which the tip of the injection syringe or fiber will penetrate the sample vial septum during aspiration or extraction of the sample.

Pattern Description: Greater than or equal to 1 millimeter per second and less than or equal to 75 millimeters per second.

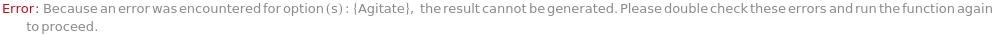

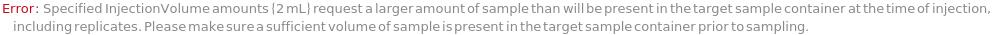

InjectionVolume

The amount of sample to draw into the liquid or headspace injection syringe for subsequent injection into the inlet.

Default Calculation: Automatically set to 25% of the LiquidInjectionSyringe volume if the SamplingMethod is LiquidInjection, or 1.5 mL if the SamplingMethod is HeadspaceInjection.

Pattern Description: Greater than or equal to 0.01 microliters and less than or equal to 2500 microliters or Null.

LiquidSampleOverAspirationVolume

The volume of air to draw into the liquid injection syringe after aspirating the sample, prior to injection.

Pattern Description: Greater than or equal to 0 microliters and less than or equal to 100 microliters or Null.

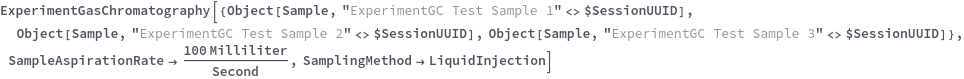

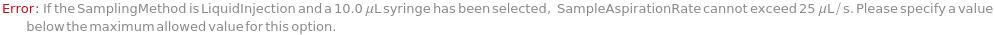

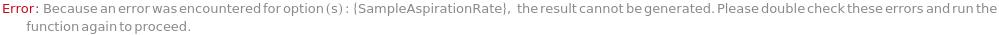

SampleAspirationRate

The volume of sample per time unit at which the sample will be drawn into the injection syringe for subsequent injection onto the column.

Default Calculation: Automatically set to 1 microliters per second if the SamplingMethod is LiquidInjection, or 10 milliliters per minute if the SamplingMethod is HeadspaceInjection.

Pattern Description: Greater than or equal to 0.1 microliters per second and less than or equal to 100 milliliters per second.

SampleAspirationDelay

The amount of time for which the autosampler will pause after drawing the injection volume into the injection syringe, while the syringe remains in the sample environment. This pause is often used to develop an equilibrium between conditions in the sample environment and syringe contents.

Default Calculation: Automatically set to 2 seconds if the SamplingMethod is LiquidInjection or HeadspaceInjection, or Null if the SamplingMethod is SPMEInjection.

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 10 seconds or Null.

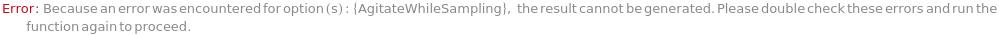

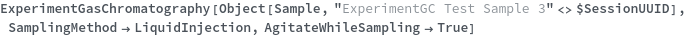

AgitateWhileSampling

Indicates whether the sample will be drawn or adsorbed while the sample is being swirled as specified by AgitationTime, AgitationTemperature, AgitationMixRate, AgitationOnTime, AgitationOffTime. This option must be True if the SamplingMethod is HeadspaceInjection, and is not available if the SamplingMethod is LiquidInjection.

Default Calculation: Automatically set to False if the SamplingMethod is SPMEInjection, or True if the SamplingMethod is HeadspaceInjection.

SPMESampleExtractionTime

The amount of time for which the Solid Phase MicroExtraction (SPME) fiber will be left in contact with the sample environment to adsorb analytes onto the fiber.

Figure 3.11: A SPMEInjection sample is extracted for the SPMESampleExtractionTime after the fiber is inserted into the sample vial at SampleVialPenetrationRate and positioned using SampleVialSpirationPosition and SampleVialAspirationPositionOffset. It is possible to extract the SPMEInjection sample while mixing using AgitateWhileSampling, in which case the sample will be extracted while mixing using the agitation parameters specified above.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

Sample Injection

InjectionInletPenetrationDepth

The distance through the inlet septum that the tip of the injection syringe's needle or Solid Phase MicroExtraction (SPME) fiber tip will be positioned during injection of the sample.

Figure 3.12: To inject a sample, the syringe's needle is plunged through the InletSeptum and into the Inlet at the InjectionInletPenetrationRate. The needle is positioned inside the inlet using the InjectionInletPenetrationDepth. Prior to injection of LiquidInjection or HeadspaceInjection samples, the needle may idle for the PreInjectionTimeDelay. If the InjectionSignalMode is PlungerUp, then the separation clock will start once the needle is in position. If it is PlungerDown, the separation clock will start when the plunger is depressed to inject the sample. LiquidInjection and HeadspaceInjection InjectionVolumes are injected into the inlet at the SampleInjectionRate. If a PostInjectionTimeDelay is specified, the needle will remain in the inlet after the injection for this amount of time before being withdrawn from the inlet. For a SPMEInjection sample, the plunger is depressed to expose the fiber containing the adsorbed analytes, which will desorb the sample for the SPMESampleDesorptionTime before the needle is withdrawn from the inlet.

Pattern Description: Greater than or equal to 10 millimeters and less than or equal to 73 millimeters.

InjectionInletPenetrationRate

The speed at which the tip of the injection syringe's needle or Solid Phase MicroExtraction (SPME) fiber will penetrate the inlet septum during injection of the sample.

Pattern Description: Greater than or equal to 1 millimeter per second and less than or equal to 100 millimeters per second.

InjectionSignalMode

Specifies whether the instrument will start the separation timer and data collection once the syringe tip is in position in the inlet but before the sample is dispensed (PlungerUp) or after the syringe's plunger has been depressed and the sample has been dispensed or exposed to the inlet (PlungerDown) during the sample injection.

PreInjectionTimeDelay

The amount of time for which the syringe's needle tip or Solid Phase MicroExtraction (SPME) fiber will be held in the inlet before the plunger is depressed and the sample is introduced into the inlet environment.

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 15 seconds or Null.

SampleInjectionRate

The volume of sample per time that will be dispensed into the inlet in order to transfer the sample onto the column.

Default Calculation: Automatically set to 50 microliters per second if the SamplingMethod is LiquidInjection, or 10 milliliters per minute if the SamplingMethod is HeadspaceInjection.

Pattern Description: Greater than or equal to 0.1 microliters per second and less than or equal to 100 milliliters per minute or Null.

PostInjectionTimeDelay

The amount of time the syringe's needle tip or Solid Phase MicroExtraction (SPME) fiber will be held in the inlet after the plunger has been completely depressed before it is withdrawn from the inlet.

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 15 seconds or Null.

SPMESampleDesorptionTime

The amount of time for which the Solid Phase MicroExtraction (SPME) fiber will be held inside the heated inlet, where analytes will be heated off the fiber and onto the column.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

Post-Injection Syringe Preparation

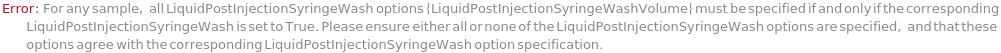

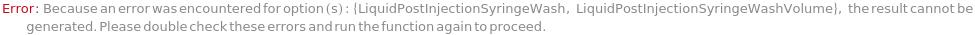

LiquidPostInjectionSyringeWash

Indicates whether the liquid injection syringe will be (repeatedly) filled with a volume of solvent which will subsequently be discarded, in an attempt to remove any impurities present prior to sample aspiration.

Default Calculation: Automatically set to True if any post-injection liquid syringe washing options are specified.

LiquidPostInjectionSyringeWashVolume

The volume of the syringe wash solvent to aspirate and dispense using the liquid injection syringe in an attempt to remove any impurities present prior to sample aspiration.

Default Calculation: Automatically set to the InjectionVolume if any post-injection liquid syringe washing options are specified.

Pattern Description: Greater than or equal to 1 microliter and less than or equal to 100 microliters or Null.

LiquidPostInjectionSyringeWashRate

The aspiration rate that will be used to draw and dispense syringe wash solvent(s) in an attempt to remove any impurities present prior to sample aspiration.

Default Calculation: Automatically set to the 5 microliters per second if any post-injection liquid syringe washing options are specified.

Pattern Description: Greater than or equal to 0.1 microliters per second and less than or equal to 100 microliters per second or Null.

LiquidPostInjectionNumberOfSolventWashes

The number of times to aspirate and discard a volume the specified SyringeWashSolvent after injecting the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any post-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

LiquidPostInjectionNumberOfSecondarySolventWashes

The number of times to aspirate and discard a volume the specified SecondarySyringeWashSolvent after injecting the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any post-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

LiquidPostInjectionNumberOfTertiarySolventWashes

The number of times to aspirate and discard a volume the specified TertiarySyringeWashSolvent after injecting the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any post-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

LiquidPostInjectionNumberOfQuaternarySolventWashes

The number of times to aspirate and discard a volume the specified QuaternarySyringeWashSolvent after injecting the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any post-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

Advanced Autosampler Options

PostInjectionNextSamplePreparationSteps

The sample preparation step up to which the autosampling arm will proceed (as described in Figures 3.5, 3.6, 3.7, and 3.10) to prepare to inject the next sample in the injection sequence prior to the completion of the separation of the sample that has just been injected. If NoSteps are specified, the autosampler will wait until a separation is complete to begin preparing the next sample in the injection queue.

Pattern Description: NoSteps, SolventWash, SampleWash, SampleFillingStrokes, or SampleAspiration or Null.

Programmatic Pattern: ((NoSteps | SolventWash | SampleWash | SampleFillingStrokes | SampleAspiration) | Automatic) | Null

Pre-Injection Syringe Cleaning

HeadspaceSyringeTemperature

The temperature at which the cylinder of the headspace syringe will be incubated throughout the experiment.

Default Calculation: Automatically set to Ambient if the SamplingMethod for the corresponding sample is HeadspaceInjection.

Pattern Description: Ambient or greater than or equal to 40 degrees Celsius and less than or equal to 150 degrees Celsius or Null.

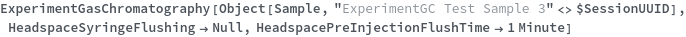

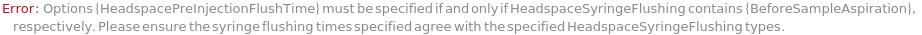

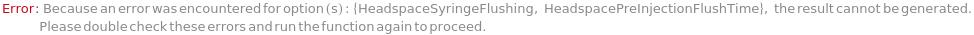

HeadspaceSyringeFlushing

Specifies whether a stream of Helium will be flowed through the cylinder of the headspace syringe without interruption between injections (Continuous), or if Helium will be flowed through the cylinder of the headspace syringe before and/or after sample aspiration for specified amounts of time.

Figure 3.13: Prior to aspiration of a HeadpsaceInjection sample, the HeadspaceInjectionSyringe may be flushed with Helium to remove any residual contamination in the syringe barrel resulting from prior injections. The HeadspaceInjectionSyringe may also be heated to minimize adsorption of analytes onto the walls of the syringe.The options shown in this figure provide control over this process.

Default Calculation: Automatically set to BeforeSampleAspiration if the SamplingMethod is HeadspaceInjection.

Pattern Description: A selection of one or more of BeforeSampleAspiration or AfterSampleInjection or Continuous or Null.

Programmatic Pattern: ((Continuous | DuplicateFreeListableP[BeforeSampleAspiration | AfterSampleInjection]) | Automatic) | Null

HeadspacePreInjectionFlushTime

The amount of time to flow Helium through the cylinder of the headspace injection syringe (to remove residual analytes in the syringe barrel) before aspirating a sample.

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 60 seconds or Null.

Post-Injection Syringe Cleaning

HeadspacePostInjectionFlushTime

The amount of time to flow Helium through the cylinder of the headspace injection syringe (to remove residual analytes in the syringe barrel) after injecting a sample.

Default Calculation: Automatically set to 3 seconds if HeadspaceSyringeFlushing includes BeforeSampleAspiration, or Null if HeadspaceSyringeFlushing is Continuous.

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 60 seconds or Null.

SPMEPostInjectionConditioningTime

The amount of time for which the Solid Phase MicroExtraction (SPME) fiber will be heat-treated in flowing Helium after sample desorption onto the column to desorb residual analytes from the fiber.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

Inlet Temperatures, Pressures, and Flow Rates

InitialInletTemperature

The temperature at which the inlet, a heated, pressurized antechamber attached to the beginning of the column (see Figure 3.1 for more details), will be held at as the separation begins.

Default Calculation: Automatically set to 275 C if the InletTemperatureProfile is Isothermal, or the first point of the InletTemperatureProfile if this temperature is possible to determine. If it is not, automatically set to 100 C.

Pattern Description: Greater than or equal to 40 degrees Celsius and less than or equal to 450 degrees Celsius or Null.

InitialInletTemperatureDuration

The amount of time into the separation to hold the inlet at its InitialInletTemperature before beginning the inlet temperature profile.

Default Calculation: Automatically set to 0.2 minutes if the InletTemperatureProfile is a temperature profile, otherwise Null.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 999.99 minutes or Null.

InletTemperatureProfile

Pattern Description: Greater than or equal to -160 degrees Celsius and less than or equal to 450 degrees Celsius or Isothermal or list of one or more {InletTemperatureRampRate, InletTemperature, InletTemperatureHoldTime} entries or list of one or more {Time, InletTemperature} entries or Null.

Programmatic Pattern: ((RangeP[-160*Celsius, 450*Celsius] | Isothermal | {{RangeP[0*Minute, 999.99*Minute], RangeP[-160*Celsius, 450*Celsius]}..} | {{RangeP[0*(Celsius/Minute), 900*(Celsius/Minute)], RangeP[-160*Celsius, 450*Celsius], RangeP[0*Minute, 999.99*Minute]}..}) | Automatic) | Null

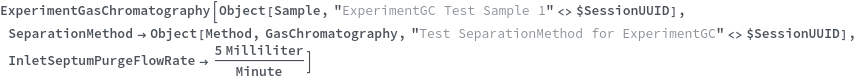

InletSeptumPurgeFlowRate

The flow rate of carrier gas that will be passed through the inlet septum purge valve, which will continuously flush the volume inside the inlet between the inlet septum and the inlet liner (see Figure 3.1).

Pattern Description: Greater than or equal to 1 milliliter per minute and less than or equal to 30 milliliters per minute.

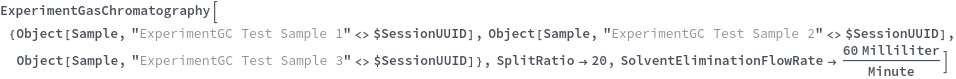

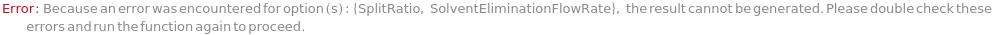

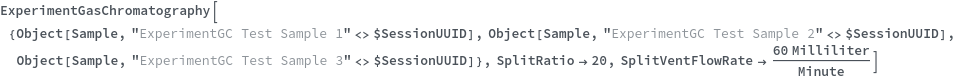

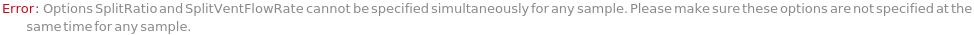

SplitRatio

The ratio of flow rate out of the inlet vaporization chamber that passes into the inlet split vent to the flow rate out of the inlet vaporization chamber that passes into the capillary column (see Figure 3.1). This value is equal to the theoretical ratio of the amount of injected sample that will pass onto the column to the amount of sample that will be eliminated from the inlet through the split valve.

SplitVentFlowRate

The flow rate through the split valve that exits the instrument out the split vent (see Figure 3.1). If no SplitlessTime has been specified, this flow rate will be set for the duration of the separation.

Pattern Description: Greater than or equal to 0.1 milliliters per minute and less than or equal to 1250 milliliters per minute or Null.

Programmatic Pattern: (RangeP[0.1*(Milliliter/Minute), 1250*(Milliliter/Minute)] | Automatic) | Null

SplitlessTime

The amount of time into the separation for which to keep the split valve closed. After this time the split valve will open to allow the SplitVentFlowRate through the split valve (cannot be specified in conjunction with SplitRatio).

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 999.99 minutes or Null.

InitialInletPressure

The pressure at which the inlet will be set (in PSI gauge pressure) at the beginning of the separation.

Default Calculation: Automatically set to twice the initial column head pressure (as determined by the InitialColumnFlowRate, InitialColumnPressure, InitialColumnResidenceTime, or InitialColumnAverageVelocity) if an InitialInletTime is specified.

Pattern Description: Greater than or equal to 0 pounds‐force per inch squared and less than or equal to 100 pounds‐force per inch squared or Null.

InitialInletTime

The time into the separation for which the InitialInletPressure and/or SolventEliminationFlowRate will be maintained.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 999.99 minutes or Null.

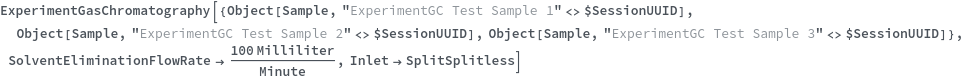

SolventEliminationFlowRate

The flow through the split valve that will be set at the beginning of the separation. If this option is specified, the split valve will be closed after the InitialInletTime. This option is often used in an attempt to selectively remove solvent from the inlet by also setting the initial inlet temperature to a temperature just above the boiling point of the sample solvent, then ramping the inlet temperature to a higher temperature to vaporize the remaining analytes.

Pattern Description: Greater than or equal to 0 milliliters per minute and less than or equal to 1250 milliliters per minute or Null.

Gas Saver

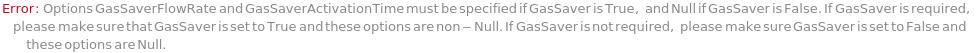

GasSaver

Indicates whether to reduce flow through the split vent after a certain time into the sample separation, reducing carrier gas consumption.

Default Calculation: If GasSaver parameters are specified, this is automatically set to True, otherwise False.

GasSaverFlowRate

The carrier gas flow rate that the total inlet flow (flow onto column plus flow through the split vent) will be reduced to when the gas saver is activated.

Pattern Description: Greater than or equal to 15 milliliters per minute and less than or equal to 1250 milliliters per minute or Null.

GasSaverActivationTime

Default Calculation: If GasSaver is True, this is automatically set to 6 residence times of the inlet liner.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 999.99 minutes or Null.

Column Pressures and Flow Rates

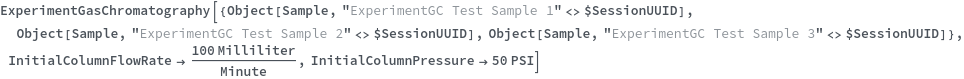

InitialColumnFlowRate

Default Calculation: Automatically set to 1.7 milliliters per minute, or calculated if another InitialColumn parameter is specified.

Pattern Description: Greater than or equal to 0 milliliters per minute and less than or equal to 150 milliliters per minute or Null.

InitialColumnPressure

Pattern Description: Greater than or equal to 0 pounds‐force per inch squared and less than or equal to 100 pounds‐force per inch squared or Null.

InitialColumnAverageVelocity

The length of the column divided by the average time taken by a molecule of carrier gas to travel through the column at the beginning of the separation.

Pattern Description: Greater than or equal to 0 centimeters per second and less than or equal to 200 centimeters per second or Null.

InitialColumnResidenceTime

The average time taken by a molecule of carrier gas to travel through the column at the beginning of the separation.

Pattern Description: Greater than or equal to 0.01 minutes and less than or equal to 999.99 minutes or Null.

InitialColumnSetpointDuration

The amount of time into the method to hold the column at a specified initial column parameter (InitialColumnFlowRate, InitialColumnPressure, InitialColumnAverageVelocity, InitialColumnResidenceTime) before starting a pressure or flow rate profile.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 999.99 minutes or Null.

ColumnPressureProfile

Pattern Description: ConstantPressure or list of one or more {ColumnPressureRampRate, ColumnPressure, ColumnPressureHoldTime} entries or list of one or more {Time, ColumnPressure} entries or Null.

Programmatic Pattern: ((ConstantPressure | {{RangeP[0*Minute, 999.99*Minute], RangeP[0*PSI, 100*PSI]}..} | {{RangeP[0*(PSI/Minute), 150*(PSI/Minute)], RangeP[0*PSI, 100*PSI], RangeP[0*Minute, 999.99*Minute]}..}) | Automatic) | Null

ColumnFlowRateProfile

Pattern Description: ConstantFlowRate or list of one or more {ColumnFlowRateRampRate, ColumnFlowRate, ColumnFlowRateHoldTime} entries or list of one or more {Time, ColumnFlowRate} entries or Null.

Programmatic Pattern: ((ConstantFlowRate | {{RangeP[0*Minute, 999.99*Minute], RangeP[0*(Milliliter/Minute), 30*(Milliliter/Minute)]}..} | {{RangeP[0*(Milliliter/Minute/Minute), 100*(Milliliter/Minute/Minute)], RangeP[0*(Milliliter/Minute), 30*(Milliliter/Minute)], RangeP[0*Minute, 999.99*Minute]}..}) | Automatic) | Null

PostRunFlowRate

The column flow rate that will be set at the end of the sample separation as the instrument prepares for the next injection in the injection queue.

Default Calculation: Automatically set to the initial column flow rate if a PostRunOvenTime is specified and a ColumnFlowRateProfile (including ConstantFlowRate) is specified.

Pattern Description: Greater than or equal to 0 milliliters per minute and less than or equal to 25 milliliters per minute or Null.

PostRunPressure

The column pressure that will be set at the end of the sample separation as the instrument prepares for the next injection in the injection queue.

Default Calculation: Automatically set to the initial column pressure if a PostRunOvenTime is specified and a ColumnPressureProfile (including ConstantPressure) is specified.

Pattern Description: Greater than or equal to 0 pounds‐force per inch squared and less than or equal to 100 pounds‐force per inch squared or Null.

Column Oven Temperature Profile

OvenEquilibrationTime

The duration of time for which the initial OvenTemperature will be held before allowing the instrument to begin the next separation.

Default Calculation: Automatically set to 2 minutes unless another value is specified by a SeparationMethod.

InitialOvenTemperature

Default Calculation: Automatically set to 50 degrees Celsius unless another value is specified by a SeparationMethod.

Pattern Description: Greater than or equal to 30 degrees Celsius and less than or equal to 450 degrees Celsius or Null.

InitialOvenTemperatureDuration

The amount of time after sample injection for which the column oven will be held at its InitialOvenTemperature before starting the column oven temperature profile.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 999.99 minutes or Null.

OvenTemperatureProfile

Default Calculation: Automatically set to a linear ramp at 20 C/min to 50 degrees Celsius below the maximum column temperature followed by a hold for 3 minutes if not specified.

Pattern Description: Isothermal or list of one or more {OvenTemperatureRampRate, OvenTemperature, OvenTemperatureHoldTime} entries or list of one or more {Time, OvenTemperature} entries or {OvenTemperature, OvenTemperatureDuration} or Null.

Programmatic Pattern: ((Isothermal | {RangeP[-60*Celsius, 450*Celsius], RangeP[0*Minute, 999.99*Minute]} | {{RangeP[0*(Celsius/Minute), 900*(Celsius/Minute)], RangeP[-60*Celsius, 450*Celsius], RangeP[0*Minute, 999.99*Minute]}..} | {{RangeP[0*Minute, 999.99*Minute], RangeP[-60*Celsius, 450*Celsius]}..}) | Automatic) | Null

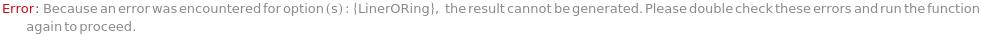

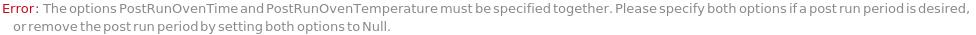

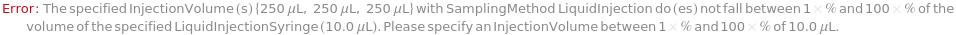

PostRunOvenTemperature

The column oven temperature that will be set at the end of the sample separation as the instrument prepares for the next injection in the injection queue.

Default Calculation: Automatically set to the initial column oven temperature if a PostRunOvenTime is specified.

Pattern Description: Greater than or equal to 30 degrees Celsius and less than or equal to 450 degrees Celsius or Null.

PostRunOvenTime

The amount of time to hold the column oven at the PostRunOvenTemperature as the instrument prepares for the next injection in the injection queue.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 999.99 minutes or Null.

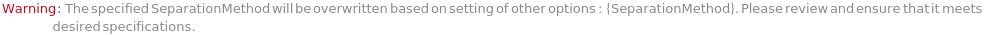

Method

SeparationMethod

A collection of inlet, column, and oven parameters that will be used to perform the chromatographic separation after the sample has been injected.

Default Calculation: Automatically creates an Object[Method, GasChromatography] using the specified options if no SeparationMethod is specified.

Detectors

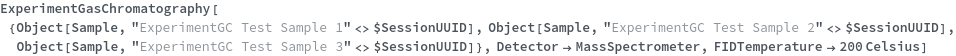

Detector

Flame Ionization Detector

FIDMakeupGas

The desired capillary makeup gas flowed into the Flame Ionization Detector (FID) during sample analysis.

Figure 3.14: The Flame Ionization Detector (FID) is a detector that uses a flame to combust the separated analytes as they elute from the separatory column. A voltage difference across the flame jet and the ion collector plate results in a measurable current when ionized combustion products are present in the flame. The detector is held at the FIDTemperature during product analysis, and a mixture of air (FIDAirFlowRate), dihydrogen gas (FIDDihydrogenFlowRate), and an inert makeup gas (FIDMakeupGas, at FIDMakeupGasFlowRate) are flowed into the flame just to sustain the flame. Because the flow rate of carrier gas in the Column may vary significantly throughout the separation, the CarrierGasFlowCorrection may be used to automatically adjust the detector gas flow rates to maintain a constant baseline signal. The current produced by the analyte combustion is measured at the FIDDataCollectionFrequency.

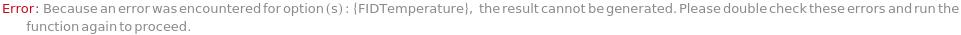

FIDTemperature

Pattern Description: Greater than or equal to 150 degrees Celsius and less than or equal to 450 degrees Celsius or Null.

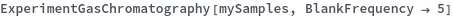

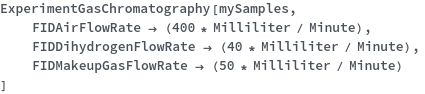

FIDAirFlowRate

The flow rate of air supplied from a Zero Air generator as an oxidant to the Flame Ionization Detector (FID) during sample analysis.

Default Calculation: Automatically set to 450 milliliters per minute if Detector is set to FlameIonizationDetector.

Pattern Description: Greater than or equal to 0 milliliters per minute and less than or equal to 800 milliliters per minute or Null.

FIDDihydrogenFlowRate

The flow rate of dihydrogen gas supplied from a Dihydrogen generator as a fuel to the Flame Ionization Detector (FID) during sample analysis.

Default Calculation: Automatically set to 8.5% of the air flow if Detector is set to FlameIonizationDetector.

Pattern Description: Greater than or equal to 0 milliliters per minute and less than or equal to 100 milliliters per minute or Null.

FIDMakeupGasFlowRate

The desired makeup gas flow rate added to the fuel flow supplied to the Flame Ionization Detector (FID) during sample analysis.

Default Calculation: Automatically set to 50 milliliters per minute if Detector is set to FlameIonizationDetector.

Pattern Description: Greater than or equal to 0 milliliters per minute and less than or equal to 100 milliliters per minute or Null.

CarrierGasFlowCorrection

Specifies which (if any) of the Flame Ionization Detector (FID) gas supply flow rates (Fuel or Makeup) will be adjusted as the column flow rate changes to keep the total flow into the FID constant during the separation.

FIDDataCollectionFrequency

The number of times per second (in Hertz) that data points will be collected by the Flame Ionization Detector (FID).

Pattern Description: 5 hertz, 10 hertz, 20 hertz, 50 hertz, 100 hertz, 200 hertz, 500 hertz, or 1000 hertz or Null.

Programmatic Pattern: ((5*Hertz | 10*Hertz | 20*Hertz | 50*Hertz | 100*Hertz | 200*Hertz | 500*Hertz | 1000*Hertz) | Automatic) | Null

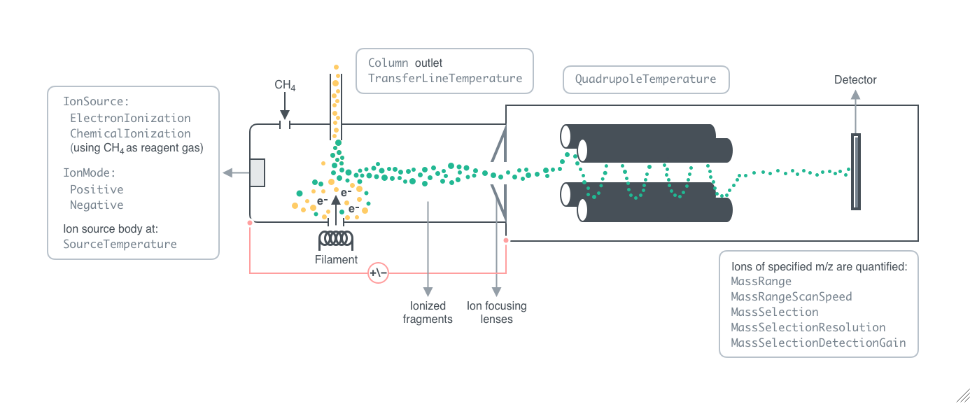

Mass Spectrometer

TransferLineTemperature

The temperature at which the segment of column the extends out of the column oven and into the mass spectrometer is held.

Figure 3.15: The Mass Spectrometer utilizes the specified IonSource to ionize the gaseous analytes as they elute from the Column. The ionized fragments are focused from the ion source into a quadrupole (parallel electrically charged rods) where they are separated by mass to charge ratio (m/z), or the ratio of one unified atomic mass unit to the charge number of the ion. Using the ElectronIonization IonSource, the gaseous analytes are ionized by a stream of electrons drawn from the filament by a voltage difference between the filament and the ion source. Using the ChemicalIonization IonSource, the ion source is filled with dilute methane, which is ionized by the electrons being drawn from the filament. The ionized methane reacts with the eluting analytes to produce more gently ionized charged fragments. Using this IonSource, the IonMode may be set to positive or negative to measure the resulting positively or negatively charged fragments. During measurement of mass spectra, the ion source and quadrupole are held at the SourceTemperature and QuadrupoleTemperature. The masses measured may be specified using the options shown here, and described below.

Default Calculation: Automatically set to 20 C above the maximum oven temperature if Detector is set to MassSpectrometer.

Pattern Description: Greater than or equal to 0 degrees Celsius and less than or equal to 400 degrees Celsius or Null.

IonSource

Specifies the method by which the analytes will be ionized. Electron Ionization uses a heated filament to create energetic electrons that collide with the gaseous analytes flowing into the mass spectrometer from the column, creating ionized fragments of the analytes that can be focused into the detector. Chemical ionization uses a reagent gas to intercept electrons from the filament to create primary ions that undergo subsequent reaction with the analytes flowing into the mass spectrometer from the column, ionizing the analytes more gently than the traditional Electron Ionization method, but also producing a different fragmentation pattern as a result of the chemical reactions taking place during ionization.

Default Calculation: Automatically set to ElectronIonization if Detector is set to MassSpectrometer.

IonMode

Indicates whether positively or negatively charged molecular fragments will be analyzed by the mass spectrometer.

SourceTemperature

The temperature at which the ionization source, where the sample is ionized inside the mass spectrometer, is held.

Pattern Description: Greater than or equal to 0 degrees Celsius and less than or equal to 300 degrees Celsius or Null.

QuadrupoleTemperature

The temperature at which the parallel metal rods, which select the mass of ion to be analyzed inside the mass spectrometer, are held.

Pattern Description: Greater than or equal to 0 degrees Celsius and less than or equal to 200 degrees Celsius or Null.

SolventDelay

The amount of time into the separation after which the mass spectrometer will turn on its controlling voltages. This time should be set to a point in the separation after which the main solvent peak from the separation has already entered and exited the mass spectrometer to avoid damaging the filament.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 1000 minutes or Null.

MassDetectionGain

The linear signal amplification factor applied to the ions detected in the mass spectrometer. A gain factor of 1.0 indicates a signal multiplication of 100,000 by the detector. Higher gain factors raise the signal sensitivity but can also cause a nonlinear detector response at higher ion abundances. It is recommended that the lowest possible gain that allows achieving the desired detection limits be used to avoid damaging the electron multiplier.

TraceIonDetection

Indicates whether a proprietary set of algorithms to reduce noise in ion abundance measurements during spectral collection, resulting in lower detection limits for trace compounds, will be used.

AcquisitionWindowStartTime

The times during the separation at which the mass spectrometer will begin to collect data using the specified index-matched MassRanges and/or MassSelections.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 1000 minutes or Null.

MassRange

MassRangeThreshold

Pattern Description: Greater than or equal to 0 and less than or equal to 99999 in increments of 1 or Null.

MassRangeScanSpeed

Programmatic Pattern: ((49 | 98 | 195 | 391 | 781 | 1562 | 3125 | 6250 | 10000 | 12500) | Automatic) | Null

MassSelection

The specific mass-to-charge ratios (m/z) and the time for which data will be collect at each specified m/z during data collection.

Programmatic Pattern: ({{RangeP[1.6, 1050, 0.1], RangeP[1*Milli*Second, 500*Milli*Second, 1*Milli*Second]}..} | Automatic) | Null

MassSelectionResolution

The m/z range window that may be transmitted through the quadrupole at the selected mass. Low resolution will allow a larger range of masses through the quadrupole and increase sensitivity and repeatability, but is not ideal for comparing adjacent m/z values as there may be some overlap in the measured abundances.

MassSelectionDetectionGain

The arbitrary scaling factor that will be used to increase the detected signal during the collection of the corresponding list of selectively monitored m/z in MassSelection.

Default Calculation: Automatically set to the specified MassDetectionGain if Selected Ion Monitoring (SIM) m/z ratios are specified.

Pattern Description: Greater than or equal to 0.1 and less than or equal to 25 in increments of 0.1 or Null.

Protocol

NumberOfReplicates

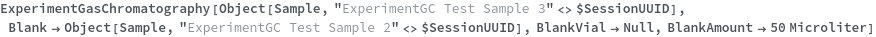

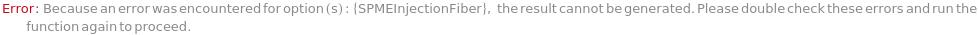

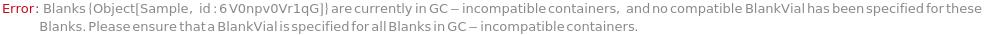

Standards

Standard

A reference compound to inject into the instrument, often used for quantification or to check internal measurement consistency.

Pattern Description: An object of type or subtype Model[Sample] or Object[Sample] or a prepared sample or Null.

StandardVial

The container in which to prepare a reference compound to inject into the instrument, often used for quantification or to check internal measurement consistency.

Pattern Description: An object of type or subtype Model[Container, Vessel] or Object[Container, Vessel] or a prepared sample or Null.

Programmatic Pattern: ((ObjectP[{Model[Container, Vessel], Object[Container, Vessel]}] | _String) | Automatic) | Null

StandardAmount

The amount of a reference compound to prepare in a vial for subsequent injection into the instrument, often used for quantification or to check internal measurement consistency.

Pattern Description: Greater than or equal to 0 micrograms and less than or equal to 2000 micrograms or greater than or equal to 0 microliters and less than or equal to 20000 microliters or Null.

Programmatic Pattern: ((RangeP[0*Microliter, 20000*Microliter] | RangeP[0*Micro*Gram, 2000*Micro*Gram]) | Automatic) | Null

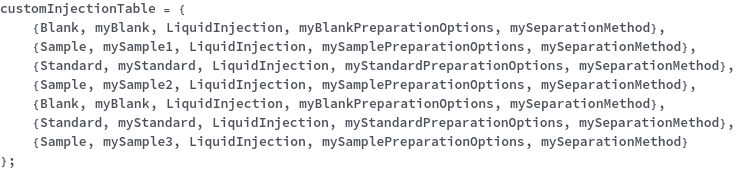

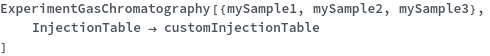

StandardFrequency

Pattern Description: Greater than 0 in increments of 1 or None, First, Last, FirstAndLast, or MethodChange or Null.

Programmatic Pattern: (((None | First | Last | FirstAndLast | MethodChange) | GreaterP[0, 1]) | Automatic) | Null

Standard Sample Preparation

StandardDilute

Indicates whether or not an aliquot of a specified liquid solution will be added to the sample's container prior to injection of the sample.

StandardDilutionSolventVolume

The volume of the DilutionSolvent to aliquot into the sample's container prior to injection of the sample.

Default Calculation: Automatically fills the sample's container to the sample container's MaxVolume with an equal volume mixture of each DilutionSolvent specified and the sample if Dilute is True.

Pattern Description: Greater than or equal to 0 microliters and less than or equal to 2500 microliters or Null.

StandardSecondaryDilutionSolventVolume

The volume of the DilutionSolvent to aliquot into the sample's container prior to injection of the sample.

Default Calculation: Automatically fills the sample's container to the sample container's MaxVolume with an equal volume mixture of each DilutionSolvent specified and the sample if Dilute is True.

Pattern Description: Greater than or equal to 0 microliters and less than or equal to 2500 microliters or Null.

StandardTertiaryDilutionSolventVolume

The volume of the DilutionSolvent to aliquot into the sample's container prior to injection of the sample.

Default Calculation: Automatically fills the sample's container to the sample container's MaxVolume with an equal volume mixture of each DilutionSolvent specified and the sample if Dilute is True.

Pattern Description: Greater than or equal to 0 microliters and less than or equal to 2500 microliters or Null.

StandardVortex

StandardVortexMixRate

The rate (in RPM) at which the sample will be spun in place to mix (vortexed) in the vortex mixer prior to analysis.

Pattern Description: Greater than or equal to 0 revolutions per minute and less than or equal to 2000 revolutions per minute or Null.

StandardVortexTime

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 100 seconds or Null.

StandardAgitate

Indicates whether or not the sample will be mixed by swirling the sample's container for a specified time at a specified rotational speed and incubated at a specified temperature prior to sampling.

StandardAgitationTime

The time that each sample will be mixed by swirling the sample's container for a specified time at a specified rotational speed and incubated at a specified temperature in the agitator prior to sample aspiration for injection onto the column.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

StandardAgitationTemperature

The temperature at which each sample will be mixed by swirling the sample's container for a specified time at a specified rotational speed and incubated at a specified temperature in the agitator prior to sample aspiration for injection onto the column.

Pattern Description: Ambient or greater than or equal to 30 degrees Celsius and less than or equal to 200 degrees Celsius or Null.

StandardAgitationMixRate

Pattern Description: Greater than or equal to 250 revolutions per minute and less than or equal to 750 revolutions per minute or Null.

StandardAgitationOnTime

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 600 seconds or Null.

StandardAgitationOffTime

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 600 seconds or Null.

Standard Sampling Method

StandardSamplingMethod

The process by which a sample will be aspirated or analytes extracted in preparation for injection of those analytes onto the column to be separated.

Default Calculation: Selects a SamplingMethod of LiquidInjection unless the sample does not contain a liquid component, in which case HeadspaceInjection is selected.

Standard Pre-Injection Syringe Preparation

StandardLiquidPreInjectionSyringeWash

Indicates whether the liquid injection syringe will be (repeatedly) filled with a volume of solvent which will subsequently be discarded, in an attempt to remove any impurities present prior to sample aspiration.

Default Calculation: Automatically set to True if any pre-injection liquid syringe washing options are specified.

StandardLiquidPreInjectionSyringeWashVolume

The volume of the syringe wash solvent to aspirate and dispense using the liquid injection syringe in an attempt to remove any impurities present prior to sample aspiration.

Default Calculation: Automatically set to the InjectionVolume if any pre-injection liquid syringe washing options are specified.

Pattern Description: Greater than or equal to 1 microliter and less than or equal to 100 microliters or Null.

StandardLiquidPreInjectionSyringeWashRate

The aspiration rate that will be used to draw and dispense syringe wash solvent(s) in an attempt to remove any impurities present prior to sample aspiration.

Default Calculation: Automatically set to the 5 microliters per second if any pre-injection liquid syringe washing options are specified.

Pattern Description: Greater than or equal to 0.1 microliters per second and less than or equal to 100 microliters per second or Null.

StandardLiquidPreInjectionNumberOfSolventWashes

The number of times to aspirate and discard a volume the specified SyringeWashSolvent prior to aspirating the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any pre-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

StandardLiquidPreInjectionNumberOfSecondarySolventWashes

The number of times to aspirate and discard a volume the specified SecondarySyringeWashSolvent prior to aspirating the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any pre-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

StandardLiquidPreInjectionNumberOfTertiarySolventWashes

The number of times to aspirate and discard a volume the specified TertiarySyringeWashSolvent prior to aspirating the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any pre-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

StandardLiquidPreInjectionNumberOfQuaternarySolventWashes

The number of times to aspirate and discard a volume the specified QuaternarySyringeWashSolvent prior to aspirating the sample in an attempt to remove any residual contamination from the liquid injection syringe.

Default Calculation: Automatically set to 3 if any pre-injection liquid syringe washing options are specified and this wash solvent is specified.

Pattern Description: Greater than or equal to 0 and less than or equal to 50 in increments of 1 or Null.

StandardLiquidSampleWash

Default Calculation: Automatically set to True for all samples with a corresponding StandardSamplingMethod of LiquidInjection.

StandardNumberOfLiquidSampleWashes

The number of times to aspirate and discard a volume of the sample using the liquid injection syringe in an attempt to remove any impurities present prior to sample aspiration.

StandardLiquidSampleWashVolume

The volume of the sample that will be aspirateed and discarded in an attempt to remove any impurities in the liquid injection syringe prior to sample aspiration.

Default Calculation: Automatically set to 125% of the StandardInjectionVolume or the maximum volume of the injection syringe, whichever is smaller, if StandardLiquidSampleWash is True.

Pattern Description: Greater than or equal to 0.01 microliters and less than or equal to 100 microliters or Null.

StandardLiquidSampleFillingStrokes

The number of times to aspirate and rapidly dispense the sample in an attempt to eliminate any bubbles from the cylinder of the liquid injection syringe prior to sample aspiration.

Default Calculation: Automatically set to 4 if a value is set for StandardLiquidSampleFillingStrokesVolume.

StandardLiquidSampleFillingStrokesVolume

The volume the sample to be aspirated and rapidly dispensed in an attempt to eliminate any bubbles from the cylinder of the liquid injection syringe prior to sample aspiration.

Default Calculation: Automatically set to 125% of the StandardInjectionVolume or the total syringe volume, whichever is smaller, if a number of LiquidSampleFillingStrokes is set.

Pattern Description: Greater than or equal to 0 microliters and less than or equal to 100 microliters or Null.

StandardLiquidFillingStrokeDelay

The amount of time to wait for any remaining bubbles to settle after aspirating and rapidly dispensing the sample in an attempt to eliminate any bubbles from the cylinder of the liquid injection syringe prior to sample aspiration.

Pattern Description: Greater than or equal to 0 seconds and less than or equal to 10 seconds or Null.

StandardSPMECondition

Indicates whether or not the Solid Phase MicroExtraction (SPME) fiber will be heat-treated in a flow of Helium prior to sample extraction to desorb residual analytes from the fiber.

StandardSPMEConditioningTemperature

The temperature at which the Solid Phase MicroExtraction (SPME) fiber will be heat-treated in flowing Helium prior to sample extraction to desorb residual analytes from the fiber.

Default Calculation: If SPMECondition is True, automatically set to the minimum recommended conditioning temperature associated with the SPME fiber.

Pattern Description: Greater than or equal to 40 degrees Celsius and less than or equal to 350 degrees Celsius or Null.

StandardSPMEPreConditioningTime

The amount of time for which the Solid Phase MicroExtraction (SPME) fiber will be heat-treated in flowing Helium prior to sample extraction to desorb residual analytes from the fiber.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

StandardSPMEDerivatizingAgent

The matrix in which the Solid Phase MicroExtraction (SPME) fiber will be allowed to react prior to sample extraction.

Pattern Description: An object of type or subtype Object[Sample] or Model[Sample] or a prepared sample or Null.

StandardSPMEDerivatizingAgentAdsorptionTime

The amount of time for which the Solid Phase MicroExtraction (SPME) fiber will be allowed to react in the specified derivatizing agent prior to sample extraction.

Pattern Description: Greater than or equal to 0 minutes and less than or equal to 600 minutes or Null.

StandardSPMEDerivatizationPosition

The extremity of the sample vial (Top or Bottom) where the tip of the Solid Phase MicroExtraction fiber will be positioned during sample aspiration or extraction.

StandardSPMEDerivatizationPositionOffset

The distance from the specified extremity of the sample vial (Top or Bottom) where the tip of the Solid Phase MicroExtraction fiber will be positioned during sample aspiration or extraction.

Pattern Description: Greater than or equal to 10 millimeters and less than or equal to 70 millimeters or Null.

Standard Sample Aspiration

StandardSampleVialAspirationPosition